RCA 103 Speaker

Welcome To ONEILL ENGINEERING

((1))WATERPUMP REBUILDING

((2))FORD F1 MASTER CYLINDER CONVERSION

((4))FORD 3/4 HUBS

((6))1949 Ford E-Brake

((8))Phono Cartridge Rebuilding

((9))Ford Flathead Generator repair

((10))Flathead Distributor

((11))Lifting a Flathead

((12))Flathead starters

((13))F2 Brake parts

((14))'49 Ford pedal bushings

((15))02' Pontiac 5.7 PCV tube

((16))02' GM horns

((18))02' FIREBIRD window motor

((20))AO Smth Rebuild

((21))A.O.SMITH PART 2

((22))AO SMITH BEARING

((24))Plastic Panel Repair

((25))HomeBrew Growler

((33))GM Power Antenna

((34))Power Antenna in Camaro

((35))Fbody power seat switch

((36))2002 ws6 ls1 oil pan removal

((37))C5 hvac auto manual

((38))2018 GM wipers

((39))American Flyer wick replacement

((40))wood column replacement

((41))Fogger repair

((43))Lionel 1615 repair

((44))Ives 3254 reverse unit repair

((46))Craftsman Circular Saw 336.27963

((50))RCP 802 Tube Chart

((51))RCA 103 Speaker

((52))Atwater Kent Power Supply

((53))1928 ATWATER KENT MODEL 40

((54))TEST EQUIPMENT

((55))Bosch Model 48

RCA 103 Speaker 1928

This page shows how to check the function of a RCA 103 Speaker

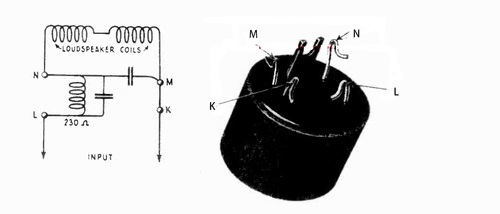

NOTE: There is a misprint in the factory service manual. Choke designations are reversed- see pic below

STEP 1: Measure OHMS on speaker ends. Should be 1.1k-1.7k ohms

STEP 2: Unsolder all 4 connections to choke and measure OHMS on N and M terminals. Should be open. Measure dosconnected wires to speaker coil- should be 1.1kohms. Measure N and L - should be 230 ohms.

REVISED FROM SERVICE MANUAL

SCHEMATIC AND PHOTO OF COIL

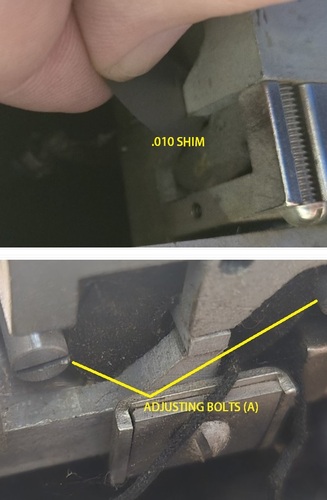

STEP 3: Alignment of thrust arm

Using .010 shim stock, insert 4 small shims in the thrust rod gaps. You can cut down a feeler gauge with tin snips.

Once 4 shims are installed loosten 2 adjusting screws on bottom (A) - then apply heat from a soldering gun

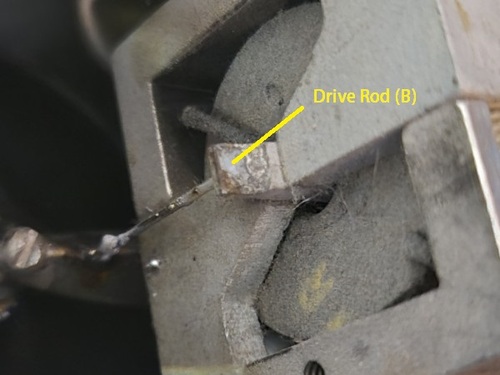

to the back attaching point of the code drive rod (B). Tighten bolts and remove shim.

Photo - heating drive rod

STEP 4 : CHECKING CONE CONNECTION